|

|

|

��Ʒ���ƣ�

|

SAϵ�л�е�ֱ�

|

|

�� �ţ�

|

SAϵ��

|

|

�� ��

|

0.00

|

|

Ʒ �ƣ�

|

|

|

|

|

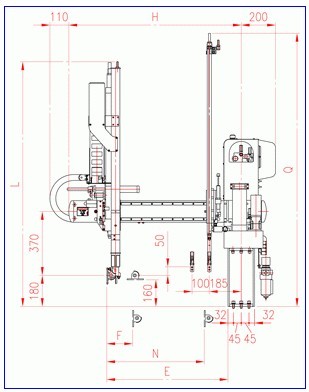

SA-Series

Servo Motor-Driven On Traverse-axis

==Mechanical Drawings==

|

Model No. |

C |

D |

E |

F |

H |

J |

K |

L |

M |

N |

|

SA700 |

180 |

370 |

774 |

150 |

1000 |

1226 |

2125 |

1417 |

160 |

560 |

|

SA900 |

180 |

370 |

894 |

200 |

1120 |

1406 |

2305 |

1617 |

160 |

680 |

|

SA1200 |

157 |

393 |

1029 |

300 |

1240 |

1646 |

2545 |

1917 |

127 |

800 |

|

Model No. |

E |

F |

H |

J |

K |

L |

N |

Q |

|

SA700S |

774 |

150 |

1000 |

1226 |

2125 |

1417 |

380 |

1582 |

|

SA900S |

894 |

200 |

1120 |

1406 |

2305 |

1617 |

500 |

1762 |

|

Model No. |

E |

F |

H |

J |

K |

L |

M |

N |

|

SA700D |

764 |

150 |

1000 |

1226 |

2125 |

1125 |

120 |

510 |

|

SA900D |

884 |

200 |

1120 |

1406 |

2305 |

1225 |

120 |

630 |

|

SA1200D |

1013 |

300 |

1240 |

1646 |

2545 |

1375 |

110 |

750 |

|

Model No. |

E |

F |

H |

J |

K |

L |

M |

N |

P |

Q |

|

SA700DS |

764 |

150 |

1000 |

1226 |

2125 |

1125 |

120 |

300 |

195 |

1155 |

|

SA900DS |

884 |

200 |

1120 |

1406 |

2305 |

1225 |

120 |

420 |

195 |

1255 |

|

SA1200DS |

1013 |

300 |

1240 |

1646 |

2545 |

1375 |

110 |

505 |

226 |

1405 | Power Source: AC 110V or 220V SINGLE PHASE

==Technical Specifications==

AC brushless servomotor AC brushless servomotor

drive on traverse axis,

accuracy within +0.1mm.

Available on 220V or

110V single phase,

please specified.

|

|

Hand-Held Controller :

One key one function operational panel with large LCD

screen, provides you with multiple languages. Operated with

conversational control method for easy and user-friendly operation.

| Application : |

|

| 8 Spare Output and 5 Spare Input terminals for coordinate with other peripheral equipment. |

| Parts Removal : |

|

| Easy maneuver with In-Mold traverse movement, it can reach unconventional path to take out difficult De-Mold parts to reduce the cost of End Of Arm Tooling. |

| Parts drop off : |

|

a) 9 programmable Cycle Position with 2 areas total of 18 points.

b) Added extra Cross Axis Setting can reach 36 points.

c) Rapid Equal Pitch Setting can reach 99 points.

d) Added extra Cross Axis Setting can reach 198 points. |

| Peripheral equipment : |

|

Connected together with conveyor, spray mist, shear cutter, sensor and

second operation machine to become an automation system. |

| Inspection : |

|

a) Reject: When detecting a reject signal from Injection Molding Machine, robot can drop the reject parts in designated point.

b) Inspection: By setting the counter quantity, robot can pick the parts into the inspection point.

c) Test Mold: By setting the counter quantity, robot can pick the test mold parts into the reject point and not set into counter.

d) Parts counter: By setting the counter quantity, robot will count good parts to reach this quantity and stop the operation. | | |

|

|

|

|